- Engineer's Current: Navigating Oil & Gas

- Posts

- Introduction to Protection Relays 2

Introduction to Protection Relays 2

Understanding Definite Time Relay

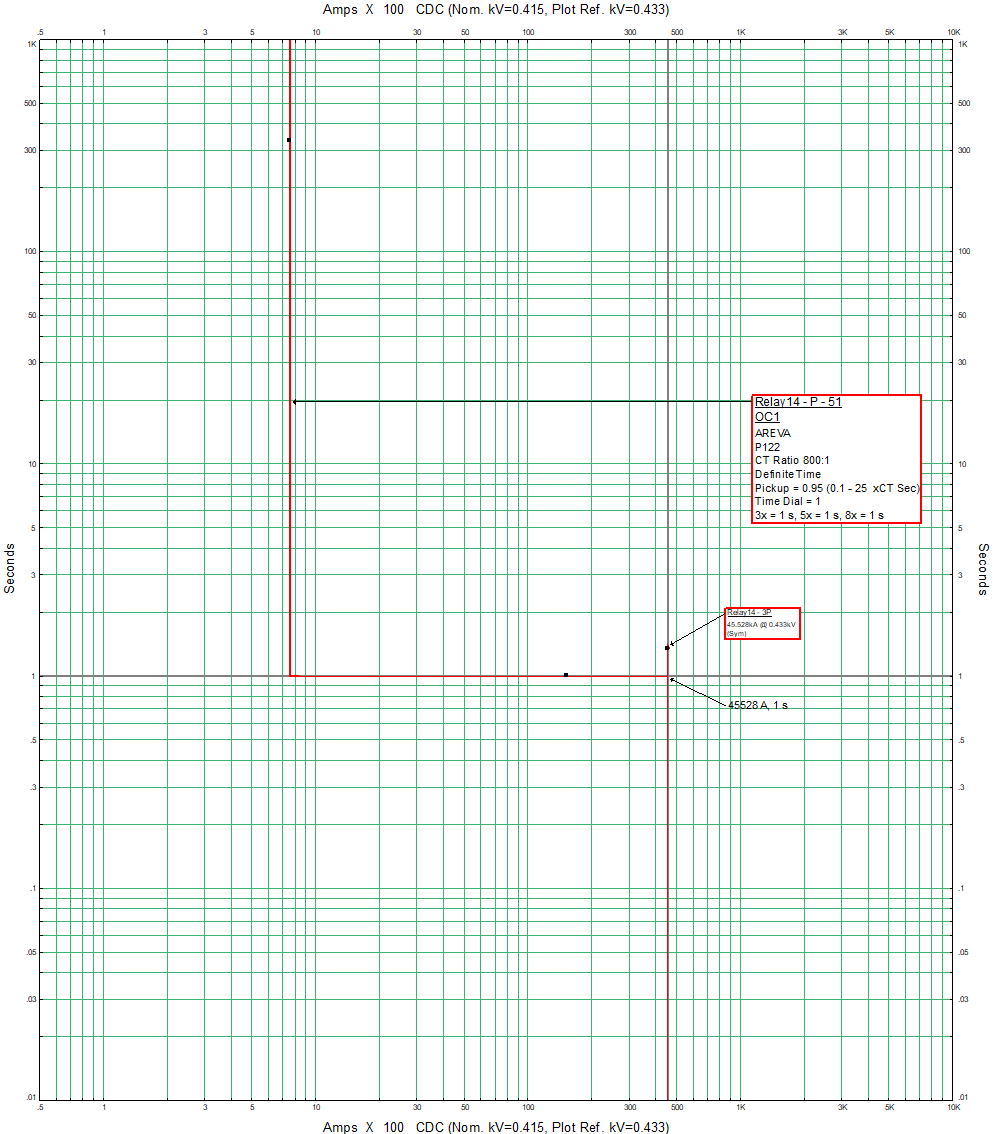

A definite time relay curve is used to describe the operating characteristic of a definite time relay in electrical engineering, particularly in the context of power system protection. A definite time relay is a type of protection relay that operates after a predetermined delay when the input (such as current or voltage) exceeds a set threshold. Unlike inverse time relays, where the delay time decreases as the magnitude of the input signal increases, definite time relays have a fixed delay time regardless of the input signal’s magnitude once the triggering threshold is exceeded.

Key Features of a Definite Time Relay Curve:

Fixed Time Delay: The relay will not operate until the set time has elapsed, regardless of how much the trigger level is exceeded. This time delay is constant.

Threshold Activation: The relay activates when the monitored parameter (e.g., current, voltage) crosses a specified threshold.

Graphical Representation: In a graph, the relay's operation can be plotted with the x-axis typically representing the parameter being monitored (like current or voltage) and the y-axis representing time. For a definite time relay, the curve would show a horizontal line at the set time delay across all values beyond the threshold.

Application: These relays are often used where a predictable timing of relay operation is necessary, regardless of the magnitude of the fault. This is useful in coordination with other protective devices in a network, allowing for selective tripping and isolation of faults.

Example

Consider a definite time overcurrent relay set to operate at 0.5 seconds whenever the current exceeds 150% of the nominal current. If the current reaches 150%, the relay will wait 0.5 seconds before tripping. If the current is 200%, 300%, or even higher, the relay still waits exactly 0.5 seconds before tripping, provided that it stays above 150%.

This behavior contrasts with inverse time relays, which would have a shorter delay for higher currents. The simplicity and predictability of definite time relays make them very useful in complex power distribution systems where coordination between different devices is crucial for effective protection.

Application

A definite time relay can play a critical role in motor jam protection by providing a reliable and straightforward method to safeguard motors from potential damage due to jams or overloads. Here’s how a definite time relay can be effectively used in such a scenario:

Understanding Motor Jam

A motor jam occurs when the motor is unable to rotate despite power being applied, typically due to mechanical blockages, overloads, or faults in the driven machinery. This can lead to excessive current draw, overheating, and potential motor damage if not quickly addressed.

Application of Definite Time Relay in Motor Jam Protection

Detection of Overcurrent:

Current Monitoring: The definite time relay is set up to monitor the current drawn by the motor. In the event of a jam, the motor will typically draw more current than normal operation due to the increased torque required to try to rotate against the jam.

Setting Thresholds: The relay is configured with a current threshold slightly above the normal operating current but below the motor’s safe operating limit to detect overcurrent conditions indicative of a jam.

Setting the Time Delay:

Fixed Delay Configuration: The time delay for the relay is set based on the motor’s characteristics and application specifics. The delay needs to be long enough to avoid nuisance tripping during normal fluctuations or start-up but short enough to protect the motor from damage. Typical delay settings might range from a few seconds up to 10-30 seconds, depending on the criticality and thermal tolerance of the motor.

Relay Activation and Response:

Trip Signal: Upon detection of overcurrent exceeding the set threshold for longer than the preset time delay, the definite time relay sends a trip signal to a circuit breaker or a contactor controlling the motor. This action disconnects the motor from the power supply, preventing further damage.

Alarming and Indication: The relay can also be configured to activate alarms or indicator lights to alert maintenance personnel of the condition, facilitating prompt intervention and troubleshooting.

Benefits of Using Definite Time Relay in Motor Jam Protection

Predictability and Reliability: The fixed time delay ensures predictable performance, which is essential for planning maintenance and operations.

Prevents Damage: By disconnecting the power in a timely manner, it prevents motor overheating and mechanical wear, extending the life of the motor.

Simplifies System Design: The use of a definite time relay simplifies the electrical protection design, making it easier to implement and maintain.

Cost-Effective: Provides a cost-effective solution to motor protection by potentially avoiding expensive motor repairs or replacements.

Using a definite time relay for motor jam protection is an effective strategy that utilizes simple yet robust technology to provide reliable protection for valuable motor-driven systems.

Join us on this electrifying journey and stay charged with "Engineer's Current"! 🌟🔌

🌟 Ignite Your Career with Engineer's Current! 🌟

Are you a young electrical engineer ready to power up your knowledge and career in the oil and gas industry? Don't miss out on "Engineer's Current" - your essential resource for in-depth insights, real-world case studies, and expert advice.

🔌 Subscribe Now and be part of an exclusive community where learning meets innovation. Stay ahead with the latest trends, deepen your expertise in electrical power systems, and connect with industry professionals.

💡 Take Charge of Your Future Today! Join "Engineer's Current" and turn your potential into high-voltage success!